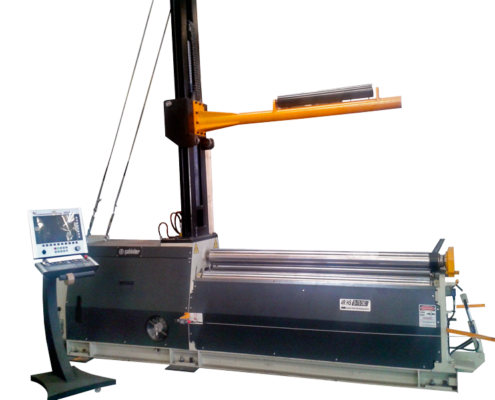

Capacities:

Width 2000mm, thickness 2 to 6mm

Technical resources

Our production unit enables us to cover all your needs for laser cutting, mechanical welding, sheet metal work, machining, assembly and surface treatment.

Machining

One four-axis CNC milling centre

First V700 four-axis CNC milling centre

Table 800×400mm

One horizontal CNC machining centre

Horizontal CNC machining centre with a 12-position indexing table + bar feeder, max. diameter 50, length 1500

Two universal lathes

Two universal milling machines

One radial drilling machine

Three column drilling machines

Metal work

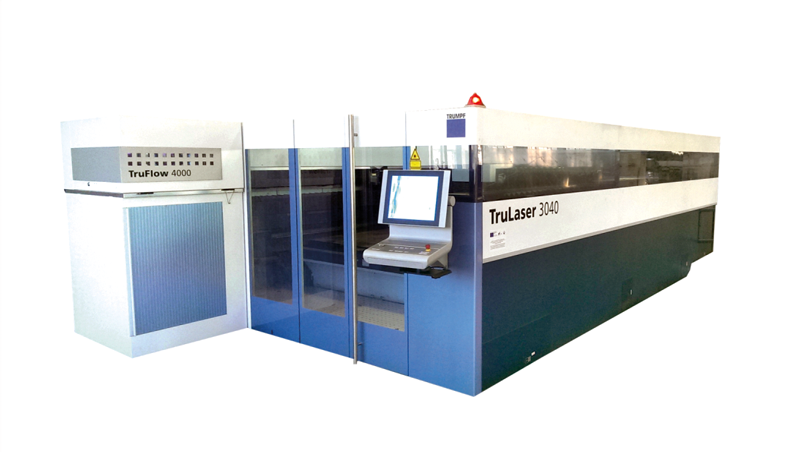

One Trumpf 3040 laser cutting machine

Capacities:

Steel 2000x4000x20mm

Stainless steel 2000x4000x15mm

Aluminium 2000x4000x10mm

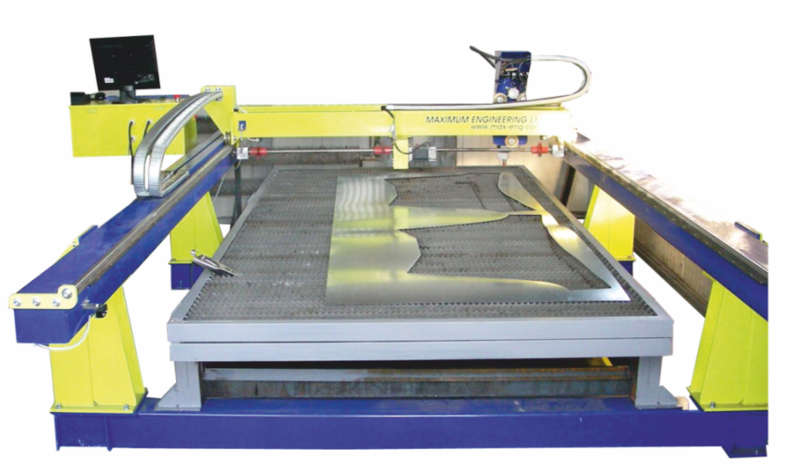

Flame cutting + NC plasma

Capacities:

Steel 2000x6000x120mm

One NC plasma tube cutter

Max. capacities:

Ø 400mm tube, length 6m

Amada 220-tonne five-axis NC bending press

Capacities:

Width 4000mm, max. thickness 10mm

Flat NC roll bender with four rollers

Mechanical welding

Capacities:

Four 500A MIG-MAG welding machines

One 400A MIG-MAG welding machine

Two 200A MIG-MAG welding machines

Two 220A TIG/MMA welding machines

Structures

Sawing

Capacities:

+/- 45° angle cutting

800mm

2 x 8m conveyor

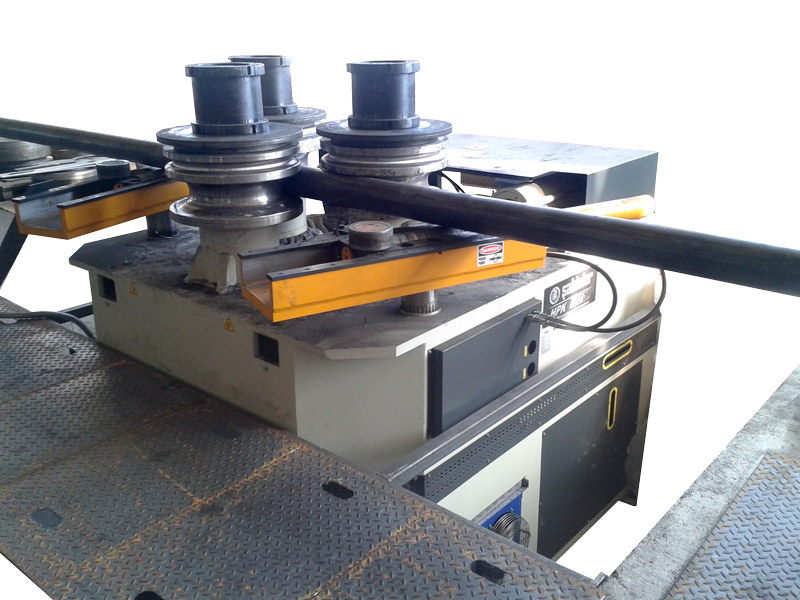

NC section bending

Capacities:

Ø 323 tube, 12mm thick

300 x 60 flat

IPE beam 360 on edge/280 on flat

Assembly and welding

Surface treatment

Metal coating

20 x 4m manual booth

Capacities:

Zinc, copper, zinc-aluminium coating

Liquid paint

20 x 7m manual booth

Capacities:

Liquid paint with pneumatic pump

with output 12l/min work at 130 bar.

Maximum dimensions 24 x 4 x 3.5H

Powder coating

Capacities:

Powder coating line with maximum passage dimensions 6 x 1.5 x 2 weighing up to 1 Tonne.

Shot blasting machine

20 x 4m manual booth

Handling, transport and certification

Handling

Four travelling cranes, 6.3 tonnes

One cross slide, 4 tonnes

One lateral slide, 4 tonnes

Two lateral slides, 2.5 tonnes

Transport

1 flatbed lorry, 19 tonnes